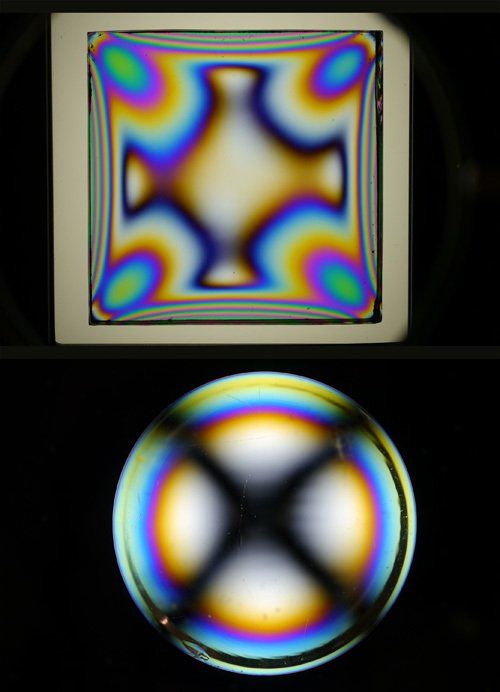

Quality control for float glass production

- Design of quality control system for float glass production (rooms, equipment, staff)

- Selection, production/purchasing and delivery of equipment customized to client’s needs

- Commissioning, training and support during start-up phase

- Turn-key solutions for laboratory and quality control